In the dynamic world of product creation, where innovation is crucial to success, manufacturers are constantly looking for cutting edge solutions that will streamline their processes and accelerate the release of products. One such innovation that has changed the game recently is laser cutting. This advanced production technique has shown to be the most effective means of accelerating the development of new products across several industries. We will discuss the causes of laser cutting’s rising popularity as well as how it has revolutionized the field of product development in this blog.

What Sets Laser-Cutting Apart from Conventional Methods?

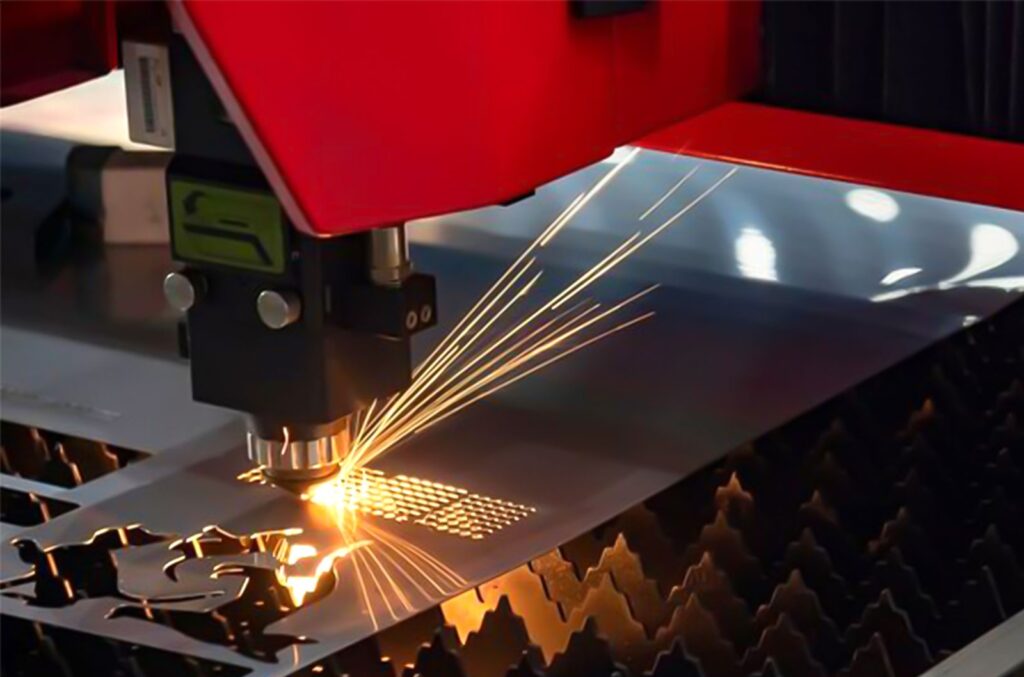

It’s important to understand how laser-cutting differs from conventional manufacturing techniques before exploring its benefits. A laser beam is used in the non-contact process of laser-cutting to accurately cut or imprint objects. When comparing this technology to traditional techniques like die-cutting or mechanical cutting, it delivers unmatched precision and versatility. Producers that wish to push the limits of product design will find laser-cutting to be an appealing option. It can create intricate shapes and complicated geometries with minimal material loss.

It’s important to understand how laser-cutting differs from conventional manufacturing techniques before exploring its benefits. A laser beam is used in the non-contact process of laser-cutting to accurately cut or imprint objects. When comparing this technology to traditional techniques like die-cutting or mechanical cutting, it delivers unmatched precision and versatility. Producers that wish to push the limits of product design will find laser-cutting to be an appealing option. It can create intricate shapes and complicated geometries with minimal material loss.

How Does Laser-Cutting Enhance Precision and Accuracy in Manufacturing?

In the process of developing new products, accuracy is crucial, and laser cutting excels at providing it in a way that traditional technologies find challenging. Manufacturers are able to make complicated parts with tight tolerances thanks to the focused laser beam’s ability to attain extremely tiny details. In fields where small, delicate parts are frequently used, like electronics, aircraft, and medical devices, this level of accuracy is very advantageous.

Additionally, laser cutting ensures constant quality throughout the production process by removing the possibility of tool wear associated with mechanical cutting methods. In order to satisfy the demanding standards of contemporary markets, where mediocre quality is not an option, this dependability is essential.

Why is Laser-Cutting an Ideal Solution for Rapid Prototyping?

The speed of product development is often determined by the efficiency of prototyping. Rapid prototyping is made possible by laser-cutting, which allows manufacturers to transform concepts into workable prototypes. Which is much faster than with conventional techniques. The non-contact nature of laser-cutting means there is no need for costly tooling or setup changes, reducing the lead time for prototype development significantly.

The speed of product development is often determined by the efficiency of prototyping. Rapid prototyping is made possible by laser-cutting, which allows manufacturers to transform concepts into workable prototypes. Which is much faster than with conventional techniques. The non-contact nature of laser-cutting means there is no need for costly tooling or setup changes, reducing the lead time for prototype development significantly.

Furthermore, a variety of materials, including metals, polymers, and composites, can be used with laser-cutting devices, enabling flexible prototyping. This adaptability plays a major role in quickening the testing and iteration stages of product development, which in turn speeds up decision-making and refining.

How Does Laser-Cutting Drive Efficiency in Mass Production?

Although laser cutting excels in prototyping, its benefits carry over into large-scale manufacturing as well. Laser-cutting devices are perfect for high-volume manufacturing because of their speed and accuracy. Productivity is maximized in production lines when materials can be quickly and consistently cut, engraved, and marked.

Moreover, mass production efficiency is raised by the automation capabilities of laser-cutting equipment. By facilitating the smooth conversion of digital designs into tangible goods, integration with computer-aided design (CAD) software lowers the possibility of human error and eliminates manufacturing bottlenecks.

What Environmental Benefits Does Laser-Cutting Offer in Product Development?

In a time when companies and customers place a high value on sustainability, it is important to consider how industrial processes affect the environment. Comparing laser-cutting to older processes reveals that it is a more environmentally responsible option. Because the laser may be set to optimise the use of raw materials, the precision of laser cutting saves material waste. Furthermore, the process’s lack of lubricants or cooling fluids reduces environmental contamination.

Since laser-cutting technology uses less power than other older manufacturing methods, its efficiency also translates into energy savings. By using laser cutting, manufacturers not only gain from its accuracy and speed, but also support a more ecologically friendly and sustainable method of product development.

How is Laser-Cutting Revolutionizing Customization in Product Design?

In the era of customization, buyers are looking for products that are more tailored to their specific tastes. This tendency is largely due to the fact that mass customization in product design is made possible by laser-cutting. For producers trying to maintain an edge in cutthroat marketplaces, the capacity to swiftly and affordably make customized parts or goods is a major plus.

In the era of customization, buyers are looking for products that are more tailored to their specific tastes. This tendency is largely due to the fact that mass customization in product design is made possible by laser-cutting. For producers trying to maintain an edge in cutthroat marketplaces, the capacity to swiftly and affordably make customized parts or goods is a major plus.

Laser-cutting allows for on-the-fly design changes without the need for extensive retooling or setup adjustments. This adaptability not only speeds up the creation of personalized goods but also creates new chances for companies to provide their clients with distinctive, customized solutions.

What Challenges and Considerations Come with Adopting Laser-Cutting Technology?

While laser-cutting offers a myriad of benefits for product development, it’s crucial to acknowledge the challenges and considerations associated with its adoption. Initial setup costs and the need for skilled operators are common hurdles that businesses may face. However, the long-term gains in efficiency, precision, and versatility often outweigh these challenges.

Furthermore, it’s critical to keep up with developments in laser-cutting technology. The capabilities of laser-cutting systems can be further improved by ongoing innovation in laser sources, control systems, and software, helping producers remain competitive in a constantly changing market.

Conclusion:

Mass manufacturing, prototyping, and design are all being approached by manufacturers in a completely new way thanks to the widespread use of laser-cutting as the go-to method for expediting the development of new products. Laser-cutting technologies is a driving force behind effectiveness and creativity because of its speed, precision, and variety.

As industries evolve and consumer expectations continue to rise, the adoption of advanced manufacturing technologies like laser-cutting becomes not just a choice but a necessity for businesses aspiring to lead in their respective domains.

Pingback: Why Laser-Cutting is the Preferred Solution to Accelerate Your New Product Development? – Laser Cutting Services

Pingback: Sustainable Practices in Electric Vehicle Charger Manufacturing - Lasercut Steel Works PVT. LTD.

You actually make it seem really easy together with your presentation but

I to find this matter to be actually something which I

believe I might by no means understand. It kind of feels too complex and extremely large for me.

I am looking forward for your subsequent publish, I’ll attempt

to get the dangle of it! Escape rooms

I was looking through some of your blog posts on this internet site

and I think this website is really informative! Keep on posting..